![]() Download this bulletin Authors – Dr Rob Arnold, Nick Mann, Jovey Farthing, Abeshaa Mahendran and Prof Allan Walton*

Download this bulletin Authors – Dr Rob Arnold, Nick Mann, Jovey Farthing, Abeshaa Mahendran and Prof Allan Walton*

HyProMag Ltd, Tyseley Energy Park, Hay Mills, Birmingham, UK B25 8DW

* Metallurgy and Materials, University of Birmingham, Edgbaston, Birmingham, B15 2SE

HyProMag is pleased to present an updated technical bulletin, demonstrating more recent trials on the use of hydrogen to separate rare earth NdFeB magnets from waste streams and on downstream magnet manufacture. This capability improvement is supported by the Accelerated Pilot Programme currently being performed in parallel with commercialisation at Tyseley Energy Park (TEP) in the UK.

HyProMag is using the patented HPMS (Hydrogen Processing of Magnet Scrap) process to efficiently separate NdFeB magnets from waste streams. This technology solves the biggest problem in the recycling space as it allows for magnets to be removed from whole components on a large scale (>400kgs +). The hydrogen converts the magnets to a demagnetised alloy powder which can then be purified to such an extent that they can be remanufactured directly back into new sintered NdFeB magnets at a fraction of the cost and environmental impact compared to primary production of magnets.

This technical bulletin describes recent trials using the HPMS process, it describes the magnets that have been created directly from selected waste streams with more than 95% recycled content and recent results demonstrating the use of recycled magnets in applications. This bulletin will be followed by further technical bulletins with additional trial data on magnets and testing within applications.

The key messages from this bulletin are as follows –

- The processes described herein are completely integrated. I.e. scrap applications into the factory and sintered NdFeB magnets out of the factory at different grades, with no miles on any of the intermediate processes.

- The magnets produced herein contain over 95% recycled content with opportunities to adjust grades through blending with virgin or recycled feed, and / or grain boundary diffusion. Blending is commonly used in commercial magnet manufacturing, and blending systems have been incorporated into the commercial developments in the UK, Germany and USA.

- The HPMS alloy powder has been upgraded to remove the oxygen rich grain boundary phase, allowing for higher grade magnets to be produced compared to many literature values for short loop recycled magnets.

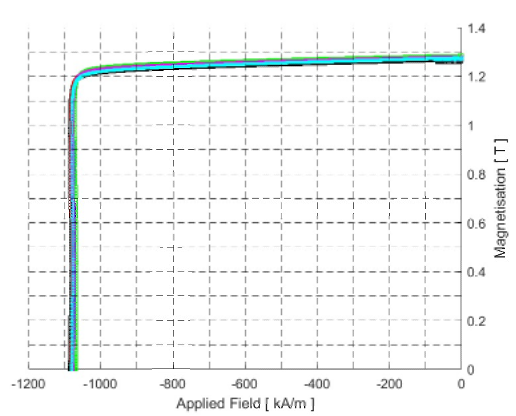

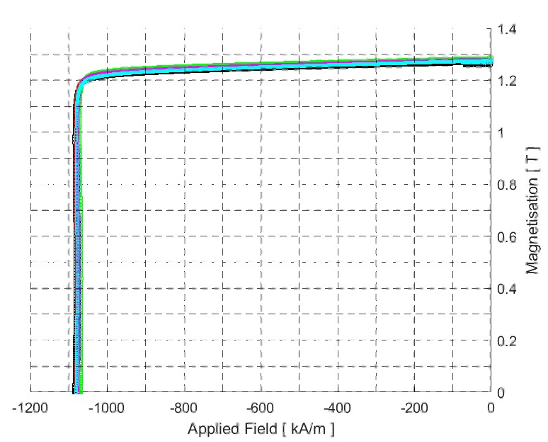

- The variability in magnetic properties observed for recycled sintered magnets produced from mixed batches of input feed shows the same variability as magnets produced from primary sources. For example, magnetic hysteresis loops for multiple recycled magnets produced from a mixed batch feed of VCM hard disk drive magnets is illustrated below, indicating minimal variability:

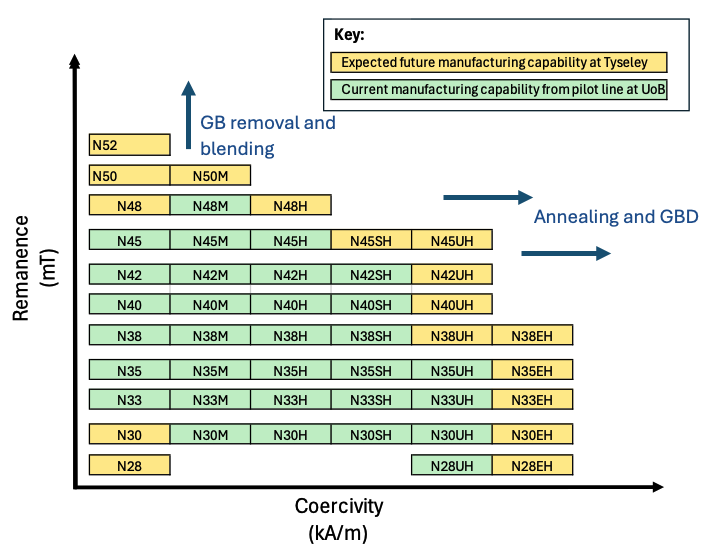

- HyProMag now has the capability of manufacturing magnets of SH grade up to and including N42SH without the use of grain boundary diffusion or the addition of primary heavy rare earths.

- The magnets produced by HyProMag have been tested in two different automotive applications for ZF Automotive and GKN Automotive. Sean Worrall (Chief Engineer Product Sustainability, GKN Automotive) commented on the success of this work at GKN Automotive. “As the key physical testing and simulation partner, we are pleased to confirm that the recycled magnets replicated expected performance exceptionally closely during testing. This means HyProMag’s short-cycled magnets can be reliably used in motor design simulation to deliver real world performance. The HPMS process enables a supply chain of sustainable, competitive, rare-earth magnets, decoupled from the problems of the virgin material supply chain.”

HyProMag Technical Bulletin – June 2025

HyProMag continues to utilise the HPMS technology (Hydrogen Processing of Magnetic Scrap) for effective and carbon friendly capture of NdFeB material from end-of-life components. This technology, developed by the University of Birmingham, is exclusively licensed to HyProMag Ltd and remains a cornerstone for the low product carbon footprint of 2.35 kg CO2 eq. recently published by HyProMag USA (LCA work performed by Minviro).

The University of Birmingham pioneered what is now described as either short loop, direct or magnet to magnet recycling whereby the hydrogen processed NdFeB powders are converted directly back into new magnets after purification by milling, alignment, pressing and sintering [1,2,3,4]. The first use of hydrogen to recycle magnets dates back to 1991 when Prof Rex Harris discussed its use to break sintered magnets down into an anisotropic NdFeB powder [5].

HyProMag is sourcing scrap from a wide variety of sources including for example electronic scrap, automotive applications, e-bikes, wind turbine magnets and MRI scanners to name a few. The end-of-life applications are qualified, categorised, and prepared for HPMS processing. The composition of the end-of-life magnets is determined by the application in which the magnets are embedded. Just like other recycling markets (eg- steel or aluminium) the waste is segregated at site into different streams where there is a narrower range of compositional variation.

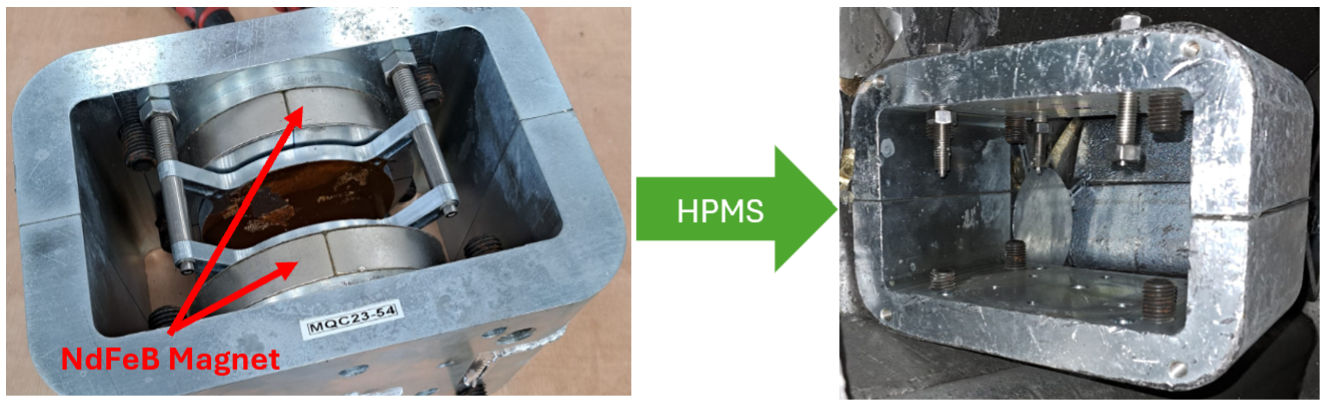

One of the advantages of HyProMag’s business model is that it is taking in end-of-life applications directly and then separating the magnets using the HPMS process [Fig.1]. This means that it has full tracking from application, through to alloy powder and then to final magnet. The magnet powder can feed multiple parts of the recycling value stream.

After HPMS, the powder is post processed to reduce the oxygen and carbon content of the powder and to remove any other impurities such as coatings. A bulk powder bed is then produced after blending which is then analysed. The scaled-up plant at TEP has automated sampling at all stages during powder processing. It has been shown in large scale trials that the powder bed can be homogenised due to the small size of the powder that is produced, leading to a uniform overall composition in each batch of material. It is possible to produce new sintered magnets from the HPMS alloy powder with >95% recycled material using the short loop processing route developed at the University of Birmingham and shown below. It is also possible to substantially change the grade of the magnets compared to the starting magnets by separation of phases in the HPMS powder and by blending with different scrap feeds, with rare earth elements, with primary strip cast alloys or alloys produced from long loop chemical processing. The University of Birmingham pioneered this type of powder blending for recycled magnets and they described the multiple recycling options in 2015 [1].

Hydrogen Processing of Magnet Scrap (HPMS)

HyProMag has ramped up the HPMS trials as part of the accelerated pilot programme in advance of the full-scale plant being completed at Tyseley Energy Park in Birmingham UK in June 2025. As part of these trials, HyProMag is producing 100kgs of NdFeB powder per week to prove the quality of the powder which is produced after purification and the subsequent grade of magnets that can be produced from different feedstocks at scale. The HPMS process removes magnets from the waste stream as a demagnetised NdFeB alloy powder which is purified by mineral processing downstream. The HPMS process is capable of separating magnets from full or parts of components / assemblies and several examples are given in this report. The majority of this process is automated with a typical cycle time from loading to unloading of 4-8 hours (Fig.1).

Interior Permanent Magnet Motors

Figure 2 shows an example of an electric bike motor (interior permanent magnet motor- IPM) prior to and after hydrogen processing as part of the recent trials. In the current trials 150 kgs of rotors were processed producing 61 kgs of powder. The separation efficiency was 98 %. A very large proportion of NdFeB magnets are embedded in IPM motors worldwide, for example in automotive electric drive units (EDUs) which can contain hundreds of magnets which are glued in place. The HPMS process produces a similar result on automotive electric drive units (EDUs) allowing for removal of magnets at a very large scale in a few hours from full rotor assemblies. As the HPMS process can remove magnets from full rotor assemblies including those on the shaft it also minimises the disassembly time. All of this significantly reduces the cost of the separation process which is a significant part of the overall costs for recycling of NdFeB magnets.

MRI Scanners

The second example shown below is for a desktop MRI unit which in this case contained 20 kg of NdFeB per unit. HyProMag (in collaboration with EMR, via the SCREAM project) has developed a rapid pre-processing technique to prepare these units for HPMS in a cost effective manner. Figure 3 below shows one of the MRI units prior to and after HPMS processing. In this case the separation efficiency was 100% in the space of 6 hours.

Hard disk drives magnets

A wide range of HPMS trials have been performed on hard disk drive (HDD) sections or on voice coil assemblies (VCMs) which have been pre-separated by a scrap handler. In Figure 4 an example is shown for a mixed batch of HDD voice coil assemblies from a mixed feed supply of real-world scrap (ie- not direct business to business with a server bank). The batch of input material in this case was in excess of 1 tonne, with individual trials targeting between100-300 kgs of input scrap. Within the scrap feed there were 17 different morphologies of VCM. Examples of these different morphologies are shown in Figure 4. As is clearly visible, there is a large variance in not only morphology but also NdFeB mass within the VCMs. Inspection of these pieces shows clearly the presence of various impurities, with minor electronics, plastic separators and rubber dampeners all present throughout the feed.

HyProMag has optimised the HPMS conditions to efficiently capture the NdFeB material whilst minimising the impurities present in the alloy powder. Separation efficiencies of 96% were realised for this scrap feed in 6 hours with up to 300kgs of input feed. In contrast to other work on VCM recycling, the removal of a thermal demagnetisation step has a significant benefit in terms of the carbon content compared to other technologies.

Following capture of the NdFeB material using HPMS, the NdFeB alloy powder is purified using mineral processing techniques. The primary aim of purification is to reduce impurities such as coating materials, oxygen and carbon.

By reducing the impurity levels within the alloy powder, it is possible to re-process the material into new sintered magnets directly with a minimal amount of blending with primary elements / alloys or with long loop separated elements / alloys. It is also possible to separate the two main phases in the magnet, thereby removing the rare earth rich grain boundary phase where the oxygen is contained from primary production [6]. This can then be replaced by powder blending to significantly improve the grade of magnet that can be produced with a minimal quantity of blending. A detailed follow-on paper is being submitted to a journal on removal of the grain boundary phase by the University of Birmingham and HyProMag Ltd so this is not included specifically in this report. However, it should be noted that this more recent work has shown that it is possible to recreate a short loop recycled magnet with a similar level of oxygen when compared to the starting magnet. When the grain boundary phase is not removed and sintered magnets are made from both phases then the oxygen content is over double the starting material. This is part of the reason that other groups have published significantly inferior magnetic properties when short loop recycling of sintered magnets.

Ultimately the grade and quality of the recycled magnets will be determined by the purity and composition of the extracted alloy powders and by careful control of processing conditions in order to achieve the optimum microstructure. Below are several examples of the magnetic properties developed from mixed scrap feeds, targeting specific grades of NdFeB magnet.

Magnet manufacture

Given the nature of end-of-life material, there is embedded variability within some scrap feeds. This variability can be mitigated against by processing production waste or through specific business to business recycling schemes (ie – magnets with known composition), but in reality, many scrap feeds will have some compositional variation. This is observed for other metals such as aluminium and as such the different grades are segregated into different material streams prior to downstream processing. It is not possible to sample the surface of magnets in the same way as aluminium to segregate on grade but as the magnets perform a certain function within different applications it is possible to significantly reduce the compositional variation by segregating magnets from specific applications. Once HPMS processing has been applied and downstream purification and blending, a uniform powder bed is produced of a known composition. At this stage the composition can be adjusted by powder blending to target specific grades of magnet. It was shown some time ago in the EU Remanence project that once HPMS powder is blended from mixed feed hard disk drives and then used to produce new sintered magnets (on commercial presses) then the variability observed across large batch sizes was the same as that observed for magnets produced from primary sources.

As discussed above, it is also possible to adjust the composition of the magnets by removal of the grain boundary phase. What cannot be adjusted is when elements are present in the matrix grains (Nd2Fe14B) within the microstructure. However, these elements can be diluted with blending as required.

An example of this compositional variability exists within hard disk drives. HyProMag has placed significant effort on understanding and accounting for this variability within the processing steps.

Voice coil motors (VCMs) and hard disk drives (HDDs) remain a key feed of interest given their large volume, ease of capture and other materials of high value found within. Below, we present a case study for the recycling of mixed feed VCMs back into new magnets with >95% recycled powder content, with hysteresis traces for output magnet products, thereby showing that variability within the scrap feed can be countered by strong technical understanding and tight process control.

Case Study – Production of sintered magnets from mixed feed VCMs

In this work HPMS processing was applied to mixed batches of VCM assemblies (as discussed above). The separated batches of material were subsequently sieved and then jet milled to an average particle size of <5 micron. This material was then aligned, pressed and vacuum sintered.

Careful control of the manufacturing conditions is key to producing well aligned, high density magnets of commercial grade. Pressing force, sintering temperature, hold times and post-sintering heat treatments are all crucial to delivering magnets to the desired specification. Below, we present second quadrant demagnetisation curves of magnet blocks created using the same mixed VCM input scrap feed, with different alloying additions.

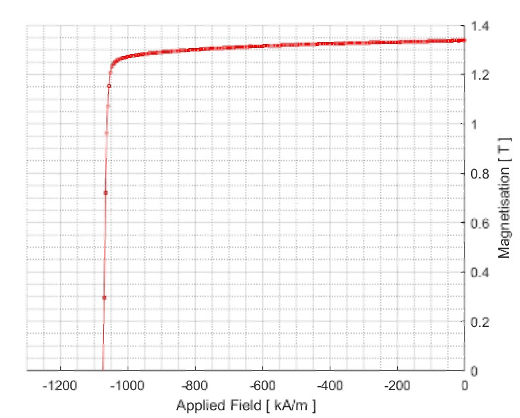

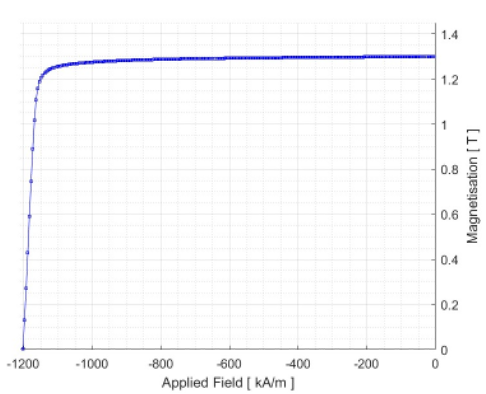

Figure 5 demonstrates a magnetic hysteresis loop for an N45M magnet produced from VCM mixed feed material with a remanence of 1.338 T, a coercivity of 1073 kA/m, and energy product of 346.5 kJ/m3. Figure 6 below demonstrates an N42M magnet supplied to HyProMag GmbH which is currently undergoing prototype testing within a loudspeaker application.

By adjustment of the alloying additions a magnet was produced with a remanence of 1.3 T, a coercivity of 1202 kA/m, and energy product of 333 kJ/m3. Both of these magnets have ≥95% of recycled content.

Variability of magnetic properties –

Multiple test blocks (recycled magnets) have been sent out to testing laboratories in different parts of the globe to assess for example the variability of magnetic performance within whole batches. The typical variability is given below in figure 7 for a magnet manufactured for a different speaker application

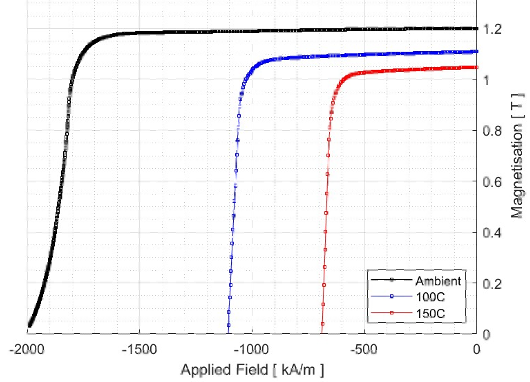

Increased magnet performance, particularly at increased temperatures.

HyProMag has been carefully working its way up the coercivity grades to increase the temperature stability of the re-sintered magnets. This has been achieved through blending of different recycled feedstocks and by blending with primary alloys and elements. An example of one of the magnet grades measured at temperature is shown below in Fig 8. HyProMag has reproducibly produced magnet grades up to UH grade and within research projects is pushing up to EH grade.

The grade table shown below in figure 9 demonstrates the grades of magnet that can be made reproducibly with the current set of equipment available to HyProMag. However, it should be noted that there is huge scope to improve these processes as the new production facility comes online at TEP with for example post sintering annealing. Further upgrades to the recycled magnets can be made by blending with higher proportions of different alloys from different end of life magnet grades, from primary alloys or long loop recycled elements or alloys. On top of this further work is being carried out on grain boundary diffusion whereby heavy rare earths are deposited on the surface of the magnets to increase the coercivity. Evidence from on-going trials and other published work indicates that at least a 35% improvement in coercivity is expected for relatively small changes in heavy rare earth content pushing the magnets into the N42 UH / N38 EH / AH grades which are commonly used in high end automotive applications.

There is also on-going work to lower the overall rare earth content of the magnets after the grain boundary phase has been removed to raise the remanence grade of the magnets.

There are on-going trials within the EU funded REESILIENCE project to demonstrate the impact of blending different feeds from long and short loop processes. It is also important to note that the parent company of HyProMag has built pilot facilities in the UK to chemically extract rare earth oxides and to pass this material through the long loop to blend with the HPMS powder, creating a 100% recycled magnet.

Ultimately there are pros and cons for all of the various recycling processes from long, medium and short loop recycling and all of them will take up some market share. This was highlighted in the paper by Walton et al in 2015 [1]. The short loop process can produce magnets at significantly lower cost, with a very small environmental footprint and it does not require the material to pass through the entire supply chain. A recycling supply chain can be built very quickly around short loop which can take long loop materials if they become cost effective and if the significant supply chain gaps are filled for example in metal making.

Case Studies – Demonstration of recycled magnets in applications

Multiple demonstration magnets have been produced by HyProMag for various applications, including automotive motors, actuators, vacuum pumps and audio products. HyProMag has worked in collaboration with multiple business partners to develop the performance criteria and the rigorous validation scheme needed to ensure that recycled magnets perform as primary magnets would of the same grade.

In collaboration with ZF Automotive & the University of Birmingham, HyProMag has recently supplied magnets for prototype testing in automotive ancillary applications which require higher coercivity and temperature stability compared to the magnets directly manufactured from VCM compositions. In this case a blend of VCM and automotive scrap magnets was created with small additions of primary alloy powders (>95% recycled content). Both secondary materials were created using HPMS. Blending of these powders produced magnets with a higher coercivity than the starting VCM material, which have been tested by ZF and a recent press article on this topic can be found here: https://www.engineerlive.com/content/recycling-and-reusing-motor-magnets.

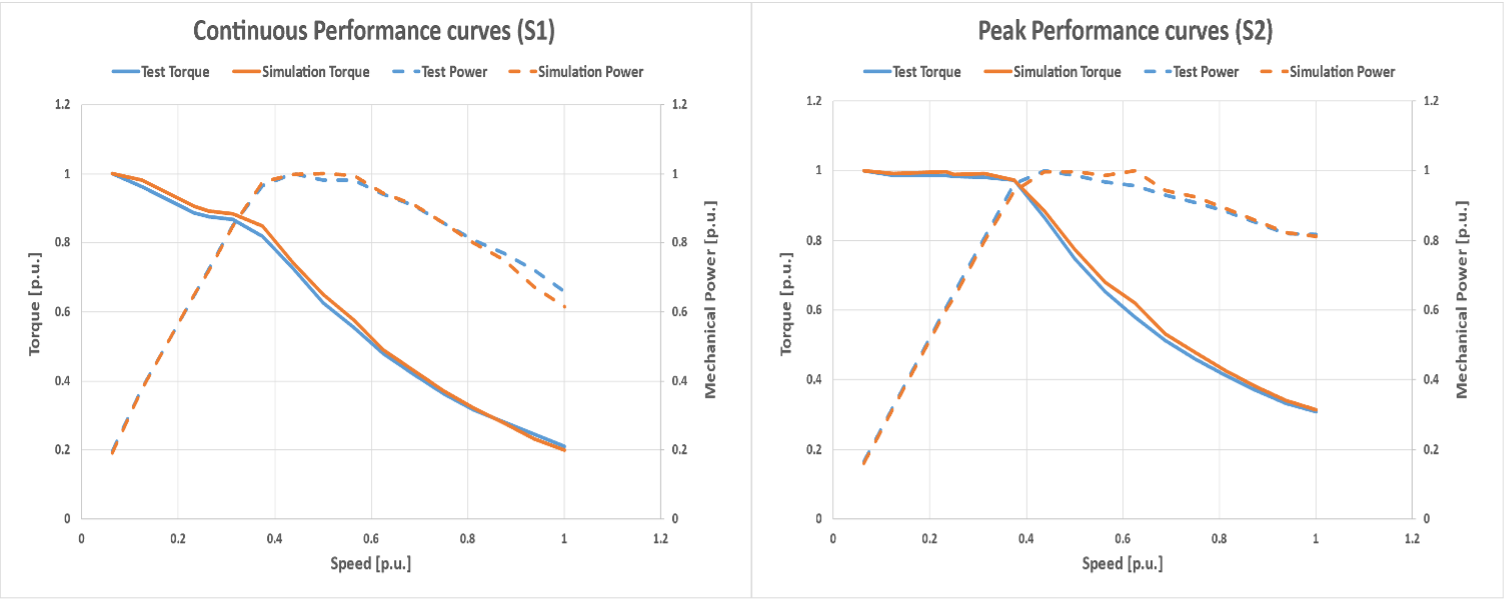

As part of the SCREAM project (funded by Driving the Electric Revolution in the UK), HyProMag manufactured recycled magnets which were built into a motor and tested against a motor simulation by project partner GKN Automotive (figure 10). For this trial grade N35SH was selected. HyProMag now has the capability of manufacturing magnets of SH grade up to and including N42SH without the use of grain boundary diffusion or the addition of primary heavy rare earths.

When comparing the simulation results to the demagnetisation tests of HyProMag recycled magnets, the magnets performed as expected from the simulation results with only slight deviations observed. This key result demonstrates that magnets produced via short-loop recycling have equivalent performance to primary magnets of the same grade, and this has been verified by simulation and physical testing work by an external partner.

Sean Worrall (Chief Engineer Product Sustainability, GKN Automotive) commented on the success of this work. “As the key physical testing and simulation partner, we are pleased to confirm that the recycled magnets replicated expected performance exceptionally closely during testing. This means HyProMag’s short-cycled magnets can be reliably used in motor design simulation to deliver real world performance. The HPMS process enables a supply chain of sustainable, competitive, rare-earth magnets, decoupled from the problems of the virgin material supply chain.”

Further test results will be released in future technical bulletins for other applications.

To discuss magnet scrap solutions and purchasing, magnet and other product sales, please contact magnets@HyProMag.com

To discuss collaboration and consultation, please contact technical@HyProMag.com

To discuss matters with HyProMag Germany, please contact info@HyProMag.de

Reference list

1] A. Walton, Y. Han, N.A. Rowson, J.D. Speight, V.S.J. Mann, R.S. Sheridan, A. Bradshaw, I.R. Harris, A.J. Williams, J. Clean.Prod 104 p236 – 241 (2015). “The Use of Hydrogen to Separate and Recycle Neodymium-Iron-Boron-type Magnets from Electronic Waste”.

2] I.R.Harris, A.Williams,A.Walton, J.D.Speight, USA Patent – US8,734,714B2 (2014).

3] C.Burkhardt, A.Walton et al, J.Mag.Mag.Mat. 588 (6) 171475, (2023), “An overview of Hydrogen assisted (Direct) recycling of rare earth permanent magnets.”

4] M. Zakotnik ∗, I.R. Harris, A.J. Williams, J.Alloys and Compounds 450 (2008) 525–53, “Possible methods of recycling NdFeB-type sintered magnets using the HD/degassing process”

5] I.R.Harris, P.J.McGuiness, J.Less-Common Metals, 172-174 (1991) 1273-1284 1273, “Hydrogen: its use in the processing of NdFeB-type magnets”.

6] A.Walton, N.Rowson, Patent number – WO2018 037239A1 (2018)