HyProMag are pleased to present milestone manufacturing results which have been achieved in 2023, alongside the advancement of the commercialisation facility at Tyseley Energy Park.

These magnets have been created by utilising the patented Hydrogen Process of Magnetic Scrap (HPMS) technology, which provides the unique advantage of liberating NdFeB material from within an end-of-life component. By avoiding the need for thermal demagnetisation or significant manual dismantling, while utilising room temperature and atmospheric pressure, HPMS is a more energy efficient process in comparison to other recycling processes such as pyrometallurgy and hydrometallurgy. There are a wide range of end-of-life components which are suitable for HPMS including hard disk drives, loudspeakers, automotive motors, magnetic filtration systems and NdFeB production scrap.

Figure 1: The grades of magnet that have been produced by HyProMag.

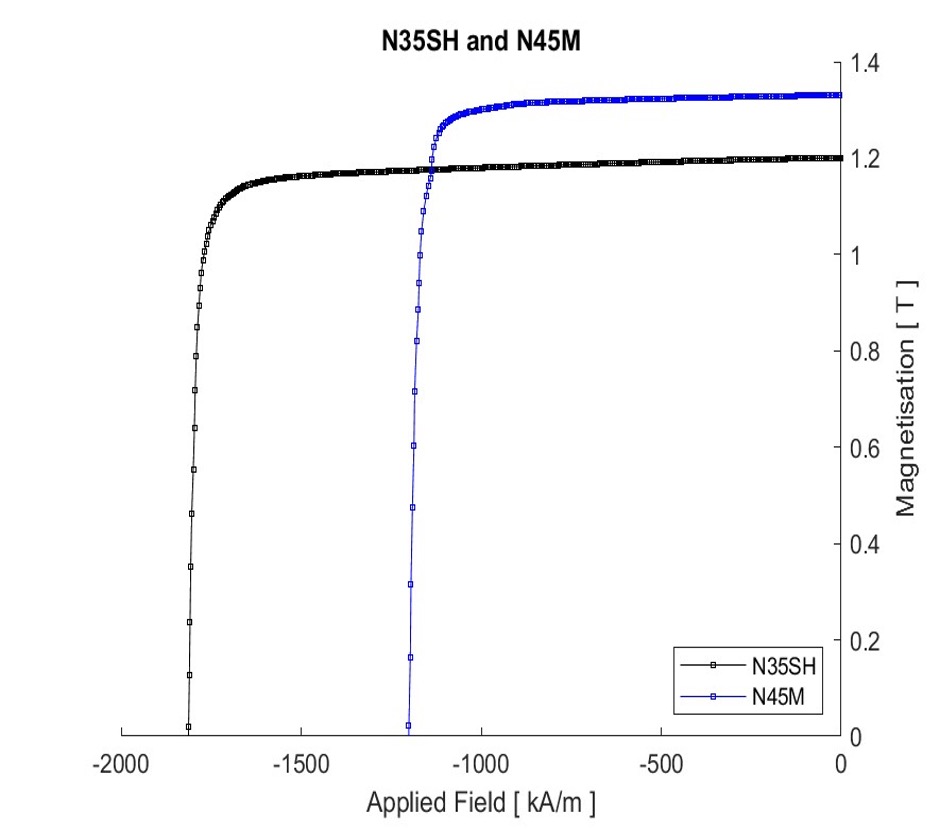

Figure 1 displays the grades of recycled magnet that have been produced by HyProMag from NdFeB feed derived from the HPMS process. Higher grades of recycled magnet are produced through refinement of the manufacturing process and through starting the recycling process with a higher grade of magnet e.g. from automotive applications. Post-sintering heat treatments unlock the potential for higher grades of recycled magnet.

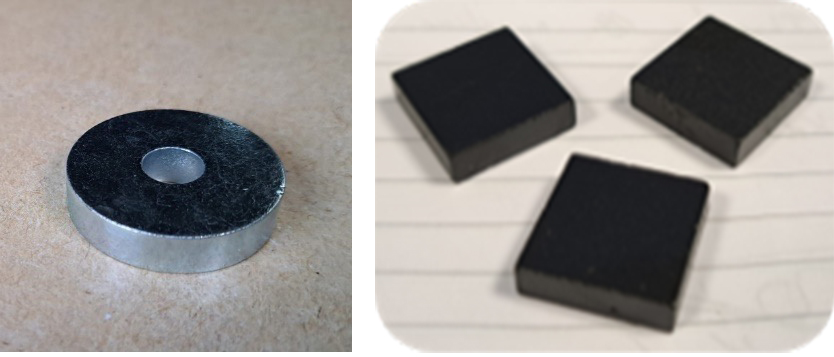

HyProMag have also been collaborating with businessess around the UK Midlands to begin exploring options for coating NdFeB magnets. Recycled magnets have been successfully coated in both epoxy and zinc as shown in Figure 2. Trials on nickel coated magnets and different passivation layers are in process. Development of coating capabilities in the UK are crucial to furthering the market for sintered magnets. There is continuous effort into producing NdFeB blocks at near net shape at HyProMag. In combination with machining capabilities within the UK, these are skills that are critical to the mass production of sintered NdFeB magnets.

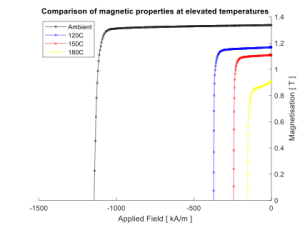

Through continued research & development with University of Birmingham, as well as the improvement of several processing steps, HyProMag are now able to manufacture magnets exceeding N45 in remanence & SH in coercivity. Figure 3 shows the hysteresis loops from magnets recycled by HyProMag. These milestones represent customer standards for both high coercivity and high remanence applications.

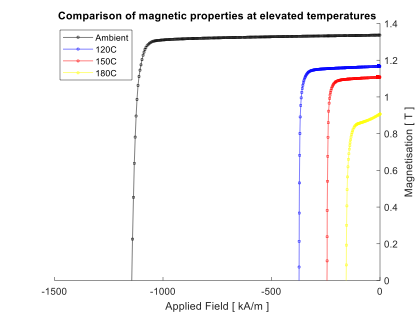

The HyProMag sintering profile is tailored according to the chemical composition which is currently verified through Inductively Coupled Plasma Optical Emission Spectrum (ICP-OES). This has allowed for significant improvement in the magnetic properties of the recycled magnets- even at elevated temperatures as shown in Figure 4. The magnets retain their ‘squareness’ at temperature which indicates that they are less likely to demagnetise under reverse fields. This also brings recycled magnets further in line with the primary market of NdFeB magnets.

HyProMag is currently providing demonstration magnets (for prototyping purposes) into various market sectors, such as pumps and loudspeakers. The abundance of products coming to their end of life in the coming years from these sectors and the grade of the magnets contained within these components make them both a suitable feedstock for recycling and a feasible magnet output.

All magnetic measurements are performed using a Magnet-Physik Permagraph C, which conforms to the following standards: IEC 60404-5, ASTM A977/A977M and DIN IEC 60404-5 as shown in Figure 5.

To discuss magnet scrap solutions and purchasing, magnet and other product sales, please contact magnets@hypromag.com

To discuss collaboration and consultation, please contact technical@hypromag.com

To discuss matters with HyProMag Germany, please contact info@hypromag.de